The technology of soil modification, developed in Germany, utilizes lime and cement supplements to mitigate ground subsidence and to increase load bearing capacity tenfold or more.

Subgrade under foundation and hard-top surfaces made of high-grade crushed stone by utilizing German stabilization process for each layer WITHOUT the use of sand.

The stabilized base is made of cast-in-place soil-concrete with a bearing capacity of at least 120 MPa (Ev2) and rate of modulus of elasticity Ev2 / Ev1 of 2.5 at most, measured in compliance with German standard DIN 18134, and specifies the level of density of the base and the amount of load that can be borne by the base WITHOUT deformation, even under intensive traffic from heavy-lift 40 t semitrucks.

The use of soil of high load-bearing capacity eliminates the need for a pile-supported foundation, which significantly accelerates the assembly of the building. The solid pre-cast slabs of reinforced concrete at the base of the columns, used as the foundation, coupled with the modified soil, allow to reach total subsidence of no more than 10 mm. This guarantees that the frame of the building will maintain its geometry perfectly.

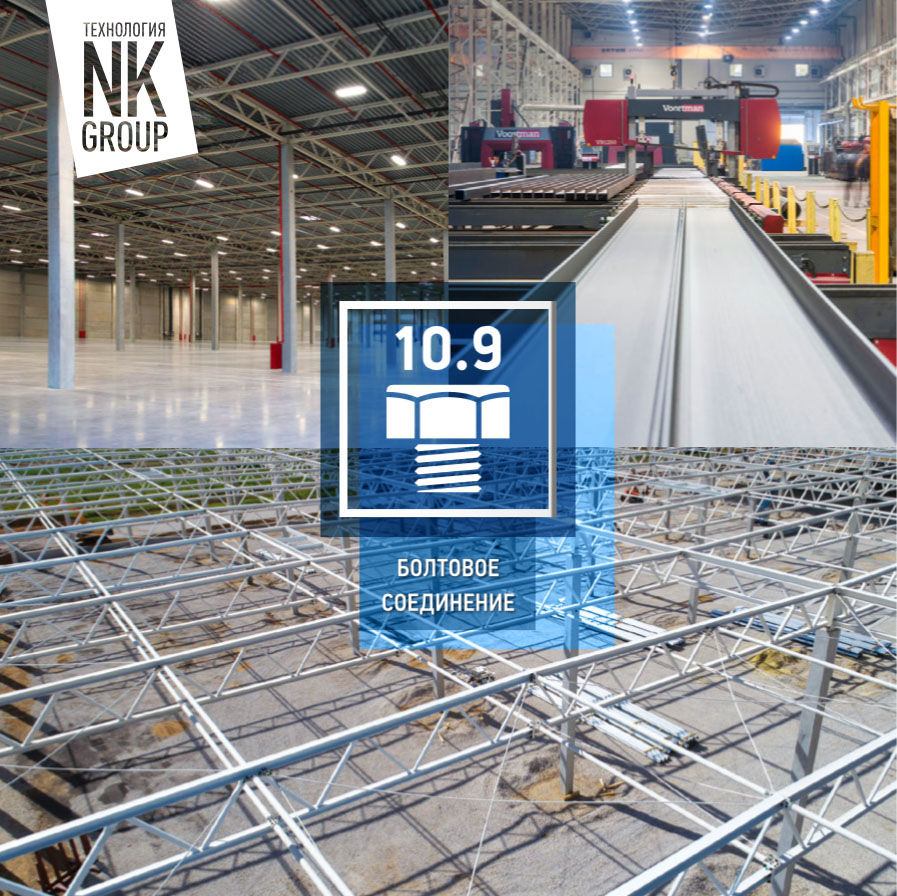

The high-precision frame of reinforced concrete has no vertical bracing between the columns and allows for any inner layout of equipment and storage racks, and does not obstruct the movement of warehousing machinery. The factory-made highly reinforced (over 200 kg/m3) concrete columns are produced with B45 grade concrete, which can endure impact blows from machinery.

The sheeting is produced at a NK-owned plant using S355J2 steel according to the EN 10025-2 standard. The assembly of the seamless frame requires no welding and utilizes a high-strength class 10.9 bolt-on connection, which decreases assembly time.

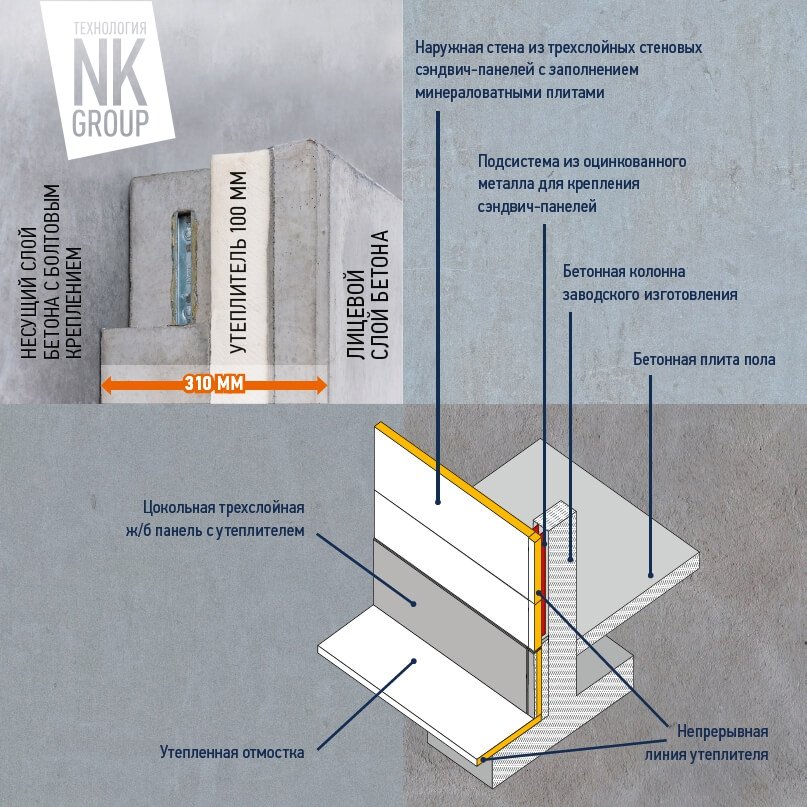

Basement manufactured at NK's in-house plant with German and Austrian equipment, is made of prefabricated reinforced concrete: three-layer reinforced concrete panel and thermal insulation.

The three-layer reinforced concrete panels 310 mm thick require no additional finishing as they have a smooth surface without pores made of high-strength waterproof (W8) frost-proof (F150) В45 grade concrete with 100 mm thick thermal insulation. Panels are fastened WITHOUT welding with galvanized bolted connections. The energy-saving continuous thermal envelope from the basement panels up to the roof increases the energy efficiency of buildings.

Gate framing (1) manufactured at NK's in-house plant with German and Austrian equipment is made of prefabricated reinforced concrete: three-layer reinforced concrete panel (310 mm thickness) with thermal insulation (100 mm). Concrete wheel guides (2) adjust traffic precisely to the gates.

Dock levelers from a European manufacturer (3) ordered by NK with heat-saving fillers, a set of galvanized protection instruments against collision (4), and dock shelter (5). Dock levelers are made of high-quality steel, have no wheel tracking, and comply with EN 1398. They are installed in prefabricated reinforced concrete pits (6). This equipment is suitable for a wide range of cargo vehicles.

Fire-resistant walls of reinforced concrete contain no burnable element and are prefabricated at a NK-owned plant and require no maintenance or operational expenses. NK walls provide solid protection against fires.

Cover structures with the application of high-strength S355J2 steel under EN 10025-2 are manufactured at NK's in-house well-equipped plant with controlled semiautomatic welding and plasma arc cutting.

We use rolled stock from European suppliers for 70 % of our products.

Framing is assembled WITHOUT welding (no human or weather factors involved) only with the application of high-strength bolted connections (10.9 grade), which fasten the steel blocks through factory-drilled holes. The diameter of such holes is only 1 mm bigger than that of bolts (with the Russian standard being 3 mm).

Galvanized profiled sheets with increased bearing capacity of 153 grade and 1 mm thickness of s320gd steel comply with European requirements for structural deflection under load, which is twice as high as required by Russian codes. The sheets are installed with the application of German 'rigid joint' technology, with a significant sheet overlap of 740 mm in length (with the Russian standard requiring only 100 mm). This forms a continuous frame with increased bearing capacity, which can endure 280 kg/m² of snow load (with the standard being 210 kg/m²).

Attachment to the framing is done using:

— HILTI technology: direct installation with special riveting nail fasteners attached to beams and trusses;

— self-tapping screws for lateral stitching of profiled sheets.

Facades in office areas are made of three-layer reinforced concrete panels 310 mm thick, which require no additional finishing, and a smooth surface without pores made of high-strength waterproof and frost-proof B45 grade concrete with 100 mm thick thermal insulation (or decorative facades of composite panels).

The windows feature increased insolation, 2 m high, in a thermally-insulated aluminum profile.

Industrial reinforced doors from European manufacturers in a metal-enclosed body with tamper-resistant stainless protectors against collision on door panels are used for finishing offices.

Flooring in office rooms is made of parquet-arranged porcelain gres.

Fire fighting in industrial buildings is carried out through a system of overhead ESFR25 sprinklers for fast fire extinguishing with water consumption of 11 l/s for one sprinkler, which improves fire safety in the building. The fire fighting system is made of grooved pipes (seamless pipe connections). Thick-wall pipes for water supply are only of SDR11 grade and endure a significant water head of 16 atm.

The ring network of external fire fighting water supply with hydrant pitch for fire brigades of 90 m at most, which exceeds the Russian standard (150 m), enables a larger number of fire brigades to join fire fighting efforts, which significantly increases the chance of saving material assets.

Industrial building

The high pre-fabrication quality of our buildings’ primary structural components is guaranteed by means of a robotic belt-line production process using German technology. The buildings are constructed in a framework method, which requires no welding.

70% of your building is prefabricated before the start of any construction operations. This significantly reduces facility construction time, while also minimizing the human and weather factors during its assembly at the building site.

Front-end engineering and design, expert review, receipt of permits and approvals for construction, building process based on German technology, installation of internal engineering systems, start-up and adjustment operations, facility commissioning, hard-surfacing and overall surrounding area development in accordance with the general plan.

Our multi-purpose buildings can be used for storage, distribution, or manufacture and are constructed to meet your precise requirements.

Since 2012 all buildings constructed by NK group comply with the FM Global property insurance standards. The facilities have a high-level of fire-resistance and constitute a highly liquid asset on the secondary property market.

Please contact us if you should have any questions

Please contact us if you should have any questions

Please contact us if you should have any questions

Please contact us if you should have any questions

Please contact us if you should have any questions

Please contact us if you should have any questions

Please contact us if you should have any questions

of industrial facilities

Please contact us if you should have any questions

Please contact us if you should have any questions

Thank you for contacting us. Your application is accepted.

Our specialist will contact you during the working day.Your application has been successfully submitted.

We will carefully study your proposal and contact you if interested.Thank you for subscribing to our newsletter

You will receive information on the specified E-mail address